Using timber house construction can be a very cost effective way to build a home. Timber construction is a traditional method of building, and it uses carefully fitted timbers. The timbers are squared off and fit together with large wooden pegs.

Lumber

Using timber for construction has many advantages. Not only is it environmentally friendly, it is also cost-effective.

The natural ability of wood to equalize temperature and humidity has many practical and psychological benefits. It can help lower blood pressure and heart rates, reduce stress, and help the body to relax.

While the cost of a house built with timber is comparable to that of a brick home, the benefits are far greater. The use of timber can reduce the amount of energy required to heat and cool a building. It can also be used to create a more comfortable interior climate.

Using wood for the framing and the walls of a house can also save time and money. This is because the frames are often made out of recycled wood.

Another advantage of using wood is the speed of construction. Timber-framed houses can be erected 30% faster than steel structures.

The cost of building a timber house is also much cheaper than that of a brick house. This can be because timber has better strength-to-weight ratio than mild steel.

Compared to a concrete or stone structure, a timber-framed house requires less time to install and less traffic obstructions. It can be moved easily and is lightweight.

Another benefit is that it uses fewer materials, and thus saves on labor and equipment costs. And while it might not seem like it, a log house can reduce the cost of heat recovery, lighting, and plumbing fixtures.

Choosing a reliable service provider for your timber house construction project is essential. Make sure you research and read customer reviews before making a final decision.

A timber-framed house can be financed by a variety of mortgage lenders.

Posts and beams

Using posts and beams in timber house construction can be a cost effective and energy efficient way to build your dream home. However, there are some things to consider before you make your next construction project.

For starters, it is important to know what you are looking for. Some examples of what you are looking for include the number of feet of posts, the type of material, and the construction method.

When choosing the right type of posts and beams for your building, consider the type of foundation you will be installing. Your foundation must be strong enough to support the structure of your home. It is also important to choose a foundation that will suit the connection style you plan on using.

You will also want to consider the quality of your post and beams. Wood can rot if you do not seal it properly. In addition, the quality of your beams will vary from manufactured beams to actual timbers. Glulam beams are a manufactured product that can be cheaper and scratch easier than their true timber counterparts.

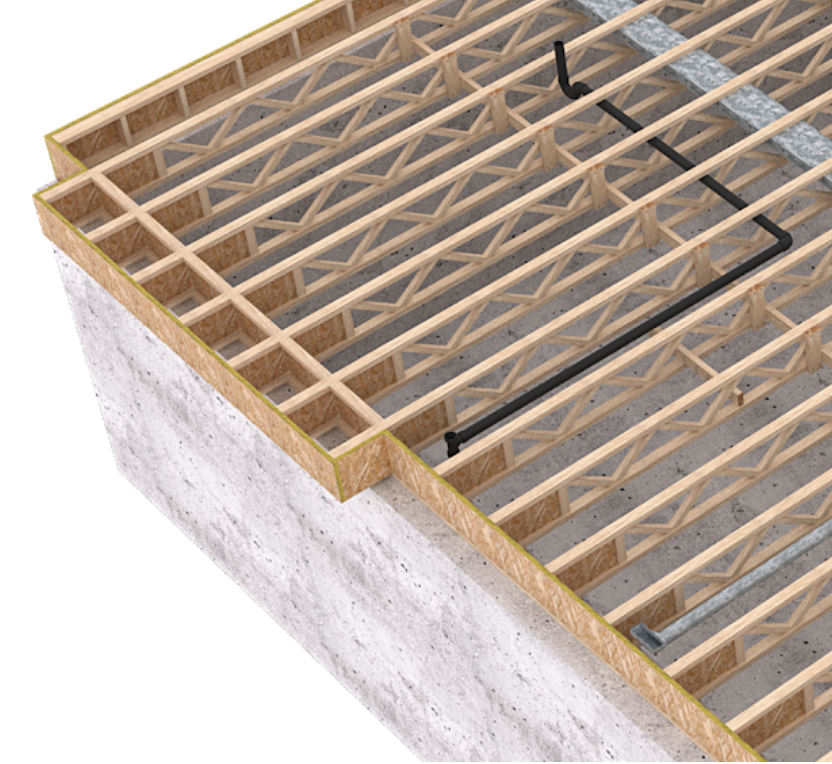

Post and beams in timber house construction are often built to be hidden, although most are labeled. I-joist installation services are also a functional and elegant design feature. For instance, they can be used as an accent in roof supports, trusses, or braces.

In addition, post and beams in timber house construction are an excellent way to create a modern home with a traditional aesthetic. A post and beam house can have high ceilings, a large floor plan, and an interior that is exposed and bold.

The other important thing to know about using posts and beams in timber house construction is that the process is flexible. It can be used in a wide variety of styles, including hybrid styles.

Structural insulated panel construction

Using structural insulated panels in Timber house construction is a great way to improve the performance and energy efficiency of your home. These innovative panels are designed to reduce the amount of energy needed for heating and cooling, while also providing a stronger and more durable structure. Choosing this type of construction can help you save money and reduce the size of your HVAC system.

These panels are made from a foam core that is surrounded by solid structural grade timber. These products can be used in the roof, walls, and floors of your home. The most common structural insulated panels are 1.2m x 2.7m sheets. They are fabricated in a factory and cut to size. They can be installed much faster than traditional framing.

When considering the use of SIPs in your Timber house construction, it is important to keep in mind that they can be prone to moisture damage. For this reason, they should not be used in flood zones. In addition, they should never be used in below-ground structures.

If you decide to use structural insulated panels, it is important to have a proper jointing system. Some manufacturers use a unique jointing system that helps minimize air leakage at connection joints. The jointing system can also lower the overall wall U value.

SIPs can be shaped like curved panels, which can be particularly beneficial in non-orthogonal geometries. They can be manufactured in panels as large as 24 feet.

SIPs are the most economical solution for your residential construction project. They are also one of the most sustainable. They can be installed faster and allow for more design flexibility. They provide superior fire resistance and moisture resistance.

Passive-house principles

Using Passive-house principles in timber house construction helps to save energy and reduce the ecological footprint of buildings. The design of a Passive-house building follows five key principles.

Air-tight construction is key to reducing energy loss through the envelope of a building. It also helps to avoid localized condensation problems. In addition, Passive-house buildings require continuous ventilation. This ensures fresh air even when windows are closed.

The use of insulated window frames and reduced thermal bridges also help in achieving a Passive-house building. The Passive-house standard delivers substantial reduction in energy and operating costs.

The concept of a Passive-house building was developed in Germany by Wolfgang Feist. He is a physicist from Northern Austria. He was the director of the Institute for Housing and the Environment in Darmstadt, and worked on a number of research projects with other architects and builders.

The first passive-house residences were constructed in Darmstadt in 1990. Four terraced houses for private clients were built following plans developed by Prof. Bott, Ridder, and Westermeyer.

In the winter of 2000-2001, the European Union funded the CEPHEUS project. The project tested the Passive-house concept in five different countries. The results showed that the concept was successful. The concept requires major reductions in heating and space-heating energy consumption.

The CEPHEUS project also demonstrated the effectiveness of Passive-house materials. The prototypes included insulated window frames, reduced thermal bridges, and CO2-regulated ventilation.

These new building components were developed as a result of research. They were then implemented in a number of prototypes.

As a result, the design of a Passive-house building is now a holistic approach. It requires a major shift in building design. This is a great opportunity for architects and builders to make more use of Passive-house concepts.